Tesla’s ambition to democratize electric vehicles has reached a critical juncture with the imminent arrival of the Model 2, a car that promises to break the price barrier and bring sustainable transportation to the masses.

Elon Musk’s pronouncements have always been bold, but his recent confirmation that Tesla will begin production of the Model 2 toward the end of 2025—at a price point as low as $10,699—has sent shockwaves through the automotive industry.

The Model 2 is not just another product in Tesla’s expanding lineup; it is a strategic response to mounting competitive pressure, shifting consumer expectations, and the urgent need for affordable clean mobility.

In a market long dominated by expensive, high-tech electric vehicles, the Model 2 stands as a potential equalizer, with the power to reshape not only Tesla’s fortunes but the entire landscape of global transportation.

Tesla’s current predicament is well-documented.

Once the undisputed leader in electric vehicles, the company has seen its market share eroded by a wave of new competitors, particularly from China.

Sales in Europe have dropped sharply, with January figures showing a 45% year-over-year decline, while rivals have surged ahead.

In China, Tesla’s most important growth market, sales of locally produced vehicles fell by nearly 50% in February 2025, reaching their lowest point since August 2022.

Meanwhile, in the United States, brand loyalty is wavering, dealerships are being vandalized by protesters, and even Tesla’s iconic Supercharger stations have been targeted.

The brand’s image has also suffered from Elon Musk’s political entanglements, which, according to recent surveys, have led a majority of UK EV buyers to avoid Tesla altogether.

In this climate, the Model 2 is more than a product launch—it is a lifeline.

The promise of a $10,699 Tesla has been met with skepticism.

How can a company known for luxury and advanced technology suddenly deliver a high-quality, fully featured electric vehicle at a price lower than most gasoline-powered compacts? The answer lies in Tesla’s relentless pursuit of manufacturing innovation, supply chain localization, and technological breakthroughs.

Tesla’s vast network of gigafactories, including facilities in Texas, Mexico, Shanghai, and Berlin, enables rapid, high-volume, and low-cost production.

The company’s adoption of giga casting—using giant molds to create large car parts in a single piece—reduces complexity, cuts labor costs, and speeds up assembly.

Tesla’s new sodium-ion battery technology, which uses more abundant and less expensive materials than traditional lithium-ion batteries, is expected to cut battery costs by up to 50% while maintaining impressive performance and durability.

Tesla’s approach to cost reduction does not come at the expense of capability.

The Model 2 is engineered to deliver acceleration that rivals or outpaces many gasoline cars, with a projected 0–60 mph time of just 5.

3 seconds thanks to a rear-wheel drive motor producing up to 210 horsepower.

The sodium-ion battery, with a capacity between 50 and 60 kWh, is expected to provide a range of 250–310 miles per charge, matching or exceeding the range of more expensive competitors.

Charging times are set to be revolutionary as well: the Model 2 will reportedly be able to charge from 0% to 80% in just 10 minutes, a dramatic leap forward that addresses one of the main anxieties of potential EV buyers.

The Model 2’s affordability is not achieved through compromise on safety or technology.

Tesla is equipping the car with a new generation of sensors and cameras, including 12-megapixel units with a 150-degree field of view, enhancing autopilot and full self-driving capabilities.

Hardware upgrades have reduced the collision avoidance system’s reaction time from 0.

7 seconds to just 0.

4 seconds, potentially saving dozens of feet in stopping distance at highway speeds.

The vehicle’s structure, built with a GigaCast chassis, is 50% more rigid than most budget EVs, and eight airbags provide protection throughout the cabin.

Tesla is also revolutionizing seat manufacturing by combining foam and upholstery into a single molded unit, possibly integrating smart sensors for heating and occupancy detection.

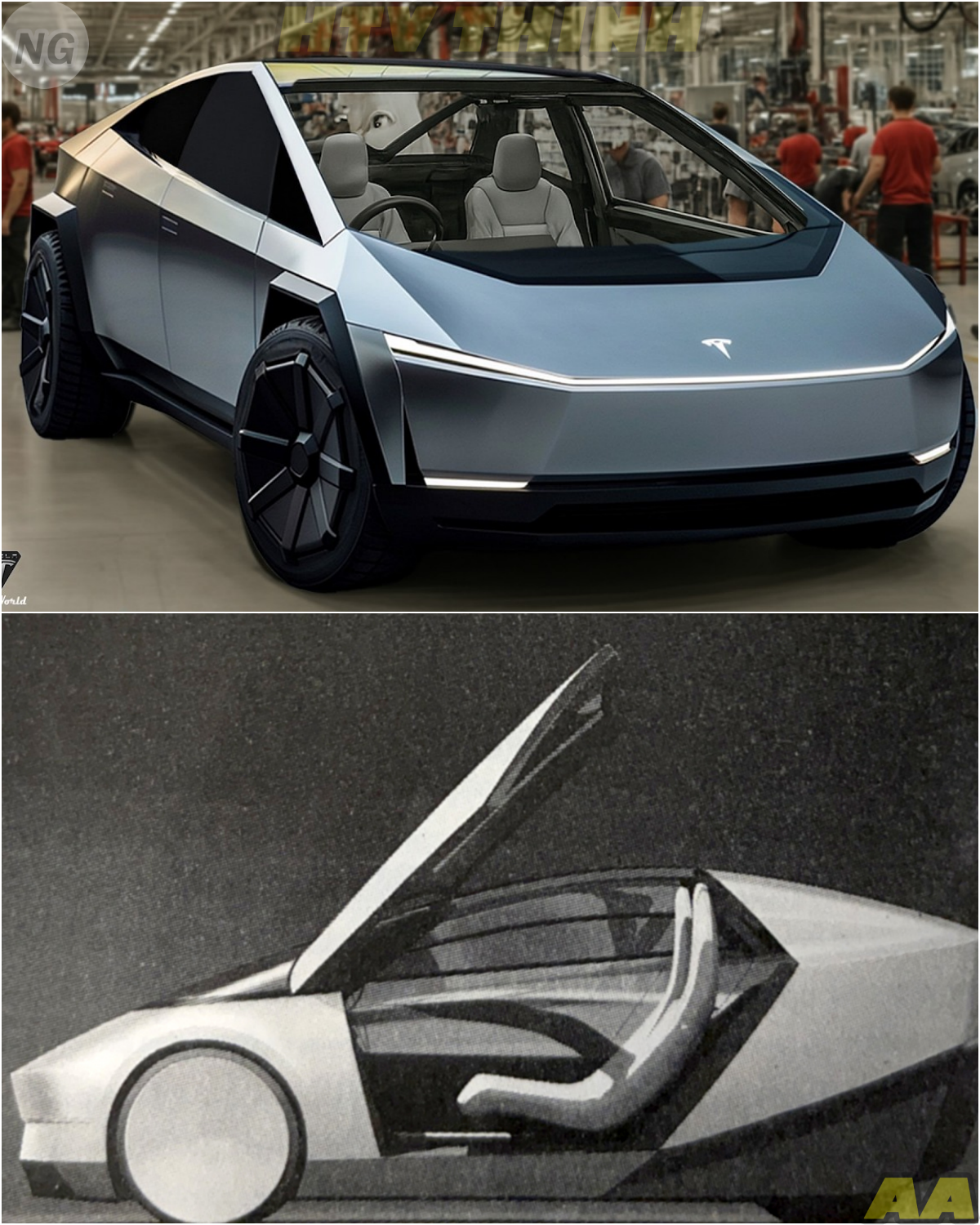

Tesla’s commitment to minimalist design continues with the Model 2.

The traditional instrument cluster is gone, replaced by a large central touchscreen that displays all vital information and controls.

This approach, already seen in the Model 3 and Cybertruck, is controversial but aligns with Tesla’s vision of a future where vehicles are increasingly autonomous and user interfaces are streamlined for simplicity and cost savings.

The Model 2’s exterior is expected to echo the Model Y’s aerodynamic lines but in a more compact, urban-friendly hatchback form.

With a drag coefficient of around 0.23–0.25, the car is engineered for maximum efficiency and range.

Production scale is key to the Model 2’s success.

Tesla’s manufacturing strategy revolves around a trifactory network: Giga Texas will handle initial production for North America, Giga Mexico is expected to reach an annual output of 2 million units by 2028, and Giga Shanghai will serve Asian and European markets.

The integration of Tesla’s Optimus humanoid robots at these facilities is expected to cut labor costs by up to 40% and enable 24/7 production.

Tesla’s aggressive expansion of its Supercharger network, now boasting over 50,000 stations worldwide, further supports the Model 2’s mass-market ambitions by alleviating charging concerns for new owners.

Despite these advances, Tesla faces real challenges.

Recent incidents, such as a fire involving several Cybertrucks, have raised questions about battery safety and manufacturing quality.

Skepticism remains about whether the sodium-ion battery can truly deliver 10,000 charge cycles without significant degradation, as Musk claims.

The push for radical cost reduction must not undermine the vehicle’s reliability or safety—a lesson Tesla has learned through years of both innovation and controversy.

Tesla’s urgency in launching the Model 2 is palpable.

With sales declining and competition intensifying, especially from Chinese automakers offering affordable EVs, the company cannot afford delays.

Analysts predict that Tesla could deliver between 300,000 and 700,000 Model 2 units by the end of 2025, with the majority of sales in China, the US, and Europe.

The Model 2’s launch is not just about reclaiming lost market share; it is about setting a new standard for what an affordable electric car can be, challenging both legacy automakers and upstart rivals.

The Model 2 is poised to become a symbol of Tesla’s relentless pursuit of efficiency, innovation, and accessibility.

Its success would validate Musk’s long-standing vision of making sustainable transport available to everyone.

If it delivers on its promises, the Model 2 could ignite a new era of mass-market EV adoption, driving down emissions and reshaping the automotive industry.

But the stakes are high.

For Tesla, this is more than a product launch—it is a battle for survival in a rapidly changing world.

The world is watching.

The Model 2’s journey from concept to reality will be a defining chapter in the story of electric vehicles.

Whether it becomes the affordable EV that finally tips the balance toward sustainable transportation, or a cautionary tale of overreach, will depend on Tesla’s ability to execute on its boldest promises yet.

For now, anticipation and skepticism run in parallel, but one thing is certain: the future of driving may soon look very different—and much more accessible—for millions around the globe.

News

😱 Rick Harrison From Pawn Stars COLLAPSES In Court After Hearing His Shocking Sentence – Then and Now 2025! ⚖️💥

Rick Harrison, the iconic face of “Pawn Stars,” has long been regarded as a shrewd businessman and a beloved television…

🔥 George Foreman FINALLY Speaks Up About Muhammad Ali – Fans Are Absolutely Fuming! 😡🥊

In the annals of sporting history, few rivalries have ever matched the intensity, drama, and lasting cultural impact of Muhammad…

🚗💥 Elon Musk FINALLY Reveals Game-Changing $7,000 Tesla Car – The Future of Driving Is Here! ⚡🔥

The automotive world has rarely witnessed a moment as electrifying as the one that unfolded when Elon Musk, the ever-unpredictable…

🌈 25 Famous Black Icons Who Hid Their True Selves Until Death – Shocking Then and Now Revelations 2025! 🕵️♂️✨

In the glittering world of fame, where every detail of a celebrity’s life is scrutinized, some truths remain stubbornly out…

💔 Dolly Parton Breaks Down in Tears Announcing the Heartbreaking Death of Her Beloved Husband 😢🎤

In the world of entertainment, love stories are often fleeting, overwhelmed by the pressures of fame, public scrutiny, and the…

😲🚫 The One Actor Keanu Reeves Absolutely REFUSES to Work With Again – Shocking Reasons Revealed! 🎬🔥

Hollywood is a world where drama, feuds, and rivalries are as much a part of the landscape as red carpets…

End of content

No more pages to load